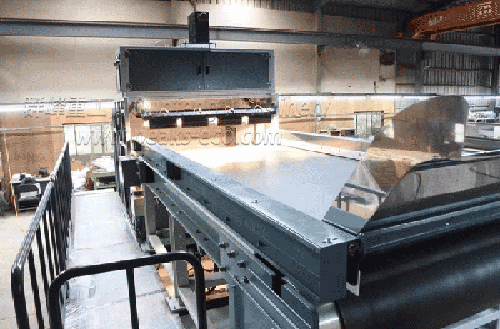

The working principle of waste sorting machine:

"The whole waste comprehensive treatment system includes three treatment workshops: waste sorting workshop, kitchen waste treatment workshop and plastic waste treatment workshop.The garbage vehicle dumps garbage on the loading platform of the garbage sorting workshop, so as to prevent the garbage from landing. The feeding platform automatically transports the garbage to the conveyor belt, and the garbage is sent to the garbage automatic sorting machine through the closed conveyor belt. The automatic garbage sorting machine classifies the garbage into kitchen waste, plastic and paper waste, metal waste, large object waste, residue waste and so on. Each type of garbage outlet is equipped with a closed conveyor belt to transport it to the corresponding workshop.

After the kitchen waste is transported to the kitchen waste treatment workshop by the closed conveyor belt, the kitchen waste biogas workshop, kitchen waste organic fertilizer workshop and humus workshop can be set according to the local situation.

The biogas produced after treatment in the kitchen waste treatment workshop is stored in the storage tank.

In addition, there are other workshops, including: plastic waste treatment workshop, packaging system, etc. The plastic and paper wastes sorted by the automatic garbage sorting machine are transported to the plastic waste treatment workshop by the closed conveyor belt. After cleaning and disinfecting the water tank, the plastic waste and paper waste are separated. The plastic waste is transported to the pulverizer through the conveyor belt for pulverization. Paper waste can be sold directly after passing through the packer. Metal waste can be sold directly after being packed and compressed by the packer through the conveyor belt.As the hazardous substances have been separated from the residue, it can be directly landfilled or incinerated, or used in the production of environmental protection building materials. "

Characteristics of waste compression station equipment:

1. The garbage is compressed and loaded in a horizontal way, with simple equipment and high reliability.

2. The whole process of garbage pressing and transportation shall be closed. The interface between the garbage can and the compressor shall be sealed with silicone double lip sealant strip to effectively prevent the overflow of waste liquid during the transportation of the garbage transportation box.

3. In the compression chamber, the bulldozer adopts various measures such as no guide rail, small clearance, horizontal movement, anti falling cover plate, etc. to ensure the smooth operation of the equipment, reduce the wear of the push head and the case, prevent the garbage from being brought into the back of the compression chamber, and reduce the cleaning work;

4. On the basis of this, it can be equipped with shifting box mechanism, rear overturn feeding mechanism, side turnover feeding mechanism, dust spray system and high pressure cleaning device, so as to adapt to various occasions such as installation operation, feeding diversification.

We are a garbage sorting machine manufacturer. In the environment industry, we mainly engage in research, manufacturing and sales of hydraulic products such as waste transfer equipment and waste sorting equipment.

没有评论:

发表评论