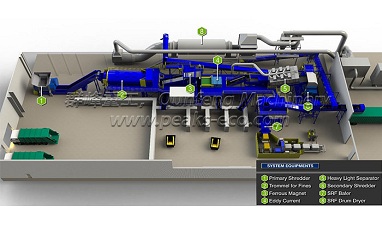

Here are some features of Peaks Eco waste sorting system:

1. Every parts of the waste sorting system is equipped with manual auto switcher and crash-stop device, locates in easy operation position, to avoid error starting or electrocution.

2. Smoothly conveying system, feeding evenly without jam; Reasonable connecting style for every transition point, without material release or accumulation.

3. The LPC control system could monitor the whole working process of waste sorting line.

4. The sealed deodorizing system as we as the unique aromatic ester spraying deodorant system, could keep the bad smell in the workshop away.

If you are interested in Peaks Eco waste sorting equipment, please contact us via www.peaks-eco.com