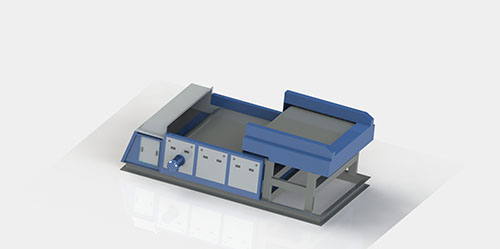

The waste paper baler is mainly composed of belt feeding, unwinding, joint connection and cutting device, transmission system, rail frame, and control device.

Principle and characteristics of waste paper baler:

Using brand baler technology, it is now designed as a dual-circuit control of the whole machine, which is more stable and reliable than the previous single-circuit control performance. The dual-circuit control reduces the internal load of the machine's electric board, and the baler structure runs more smoothly and stably between each circuit. As a manufacturer of balers, we have superior performance, more reliable quality, easier and more convenient inspection and debugging, and the first to adopt photoelectric control for the retracting clutch. The working principle of the horizontal baler machine is to complete the baling through tension, heat capacity, tape cutting, and bonding. The professional baler factory produces a wide range of applications. No matter the size of the packaging, you can pack without adjusting the machine. The packaging baler is a mechanical structure, and some of the imported baler parts are used. The rear blade is stable and reliable, easy to adjust, and the baler is reasonably priced.

Installation Precautions

1. Some parts of this packer are packed in boxes and some parts are bundled for transportation. After receiving the goods, users must carefully check the packing list to avoid loss during transportation.

2. The foundation construction must be carried out in accordance with the foundation plan and leveled with a spirit level.

3. The dirt must be cleaned up before the machine is installed. If the surface of the parts is corroded, it should be cleaned with kerosene.

4. Hoist the host after the foundation is solidified.

5. When installing the hydraulic control system, the joints should be filled with "O" seals to avoid oil leakage.

6. Install the main pump valve oil circuit, all pipelines must be cleaned, and the oil pump station is placed and leveled. Clean the inside of the oil tank to remove the dirt that enters during transportation, and tie the oil pipe clamps to prevent oil leakage caused by vibration.

7. According to the electrical schematic diagram, install all the lines to ensure the safe operation of the baler.

Waste Paper Baler

Advantages of the waste paper baler

This product has the characteristics of good rigidity, toughness and stability, beautiful appearance, convenient operation and maintenance, safety and energy-saving, and low investment cost of equipment basic engineering. It is widely used in various waste paper factories, old waste recycling companies, and other units and enterprises. It is suitable for packaging and recycling old waste paper, plastic straw scales, etc. It is a good equipment to improve labor efficiency, reduce labor intensity, save manpower, and reduce transportation costs.

1. It has the characteristics of small size, lightweight, low movement inertia, low noise, stable movement, and flexible operation.

2. It has a wide range of applications. It can be used as a waste paper packaging equipment, but also as processing equipment for packaging and compacting similar products.

3. PLC control, with the man-machine interface (touch screen) and inspection type monitoring, synchronous action indicator diagram with error warning, and the length of the block can be set.

4. The floating necking design in the left, right, and up directions is conducive to the automatic distribution of pressure on all sides and can be widely used for packing different materials.

5. Automatic strapping to improve the speed of packing.

6. The pusher cylinder and the pusher head are connected by a spherical structure, which has good reliability and the service life of the oil seal.

long.

7. The feeding port is equipped with a distributed shearing knife, which has high cutting efficiency.

8. Low noise hydraulic circuit design, high efficiency, and low failure.

9. Easy to install, without foundation.

10. A horizontal structure can be equipped with conveyor belt feeding or manual feeding.

11. Button operation, PLC control, safe and reliable.