AI Ground | Construction Waste Processing From Manual Sorting To Intelligent Sorting, Qunfeng Heavy Industry Innovation Success Again

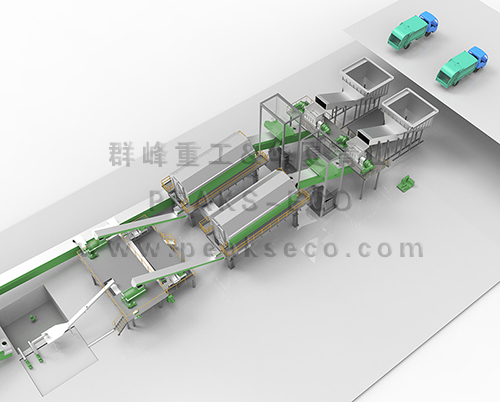

The emergence of artificial intelligence has brought about a subversive change and influence to the production structure and production relations. Today's artificial intelligence is not only used in household, finance, retail, transportation, and other industries but also introduced waste sorting industry, such as construction waste sorting is part of. At present, China's comprehensive resource treatment capacity of construction waste is still in the initial stage, facing great challenges such as the difficulty of complex material treatment, lack of intelligent treatment, and weak vertical ductility of the scheme. The future comprehensive resource treatment of construction waste is bound to focus on intelligence, integration, and the value chain.

In the process of construction waste treatment, it is found that waste bricks, tiles, stone, and other wastes are inevitably mixed with waste wood, plastic, and other wastes, thus forming "mixed waste". In order to realize the recycling of construction waste, for example, to separate and sort the mixed waste, the remaining is the recycled building materials. So what are the solutions in this area of garbage sorting?

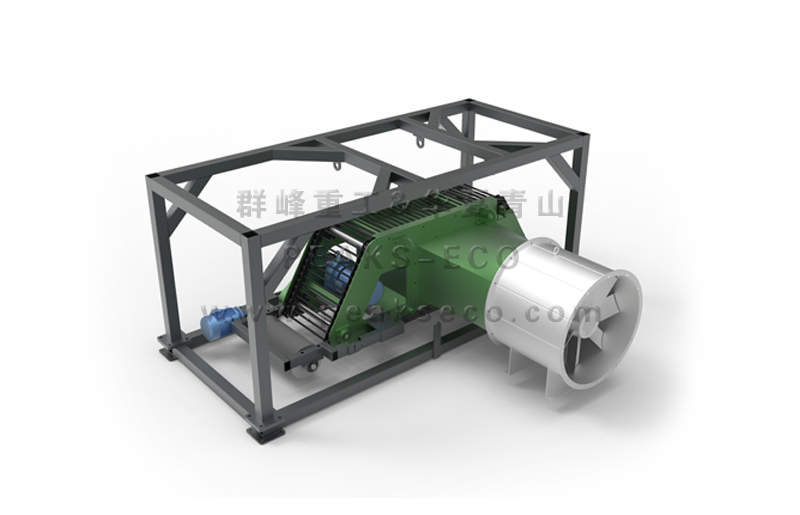

Negative pressure air separator

Using the effect of suction (negative pressure), the mixed waste in the light material sorting out, mainly including plastic, paper, dry leaves, etc. The negative pressure air separator produced and developed by Qunfeng Heavy Industry integrates the functions of sorting and dust removal, which not only reduces the dust and improves the working efficiency of the equipment, but also ensures that the screening rate can reach more than 85%, which greatly ensures the impurity removal effect.

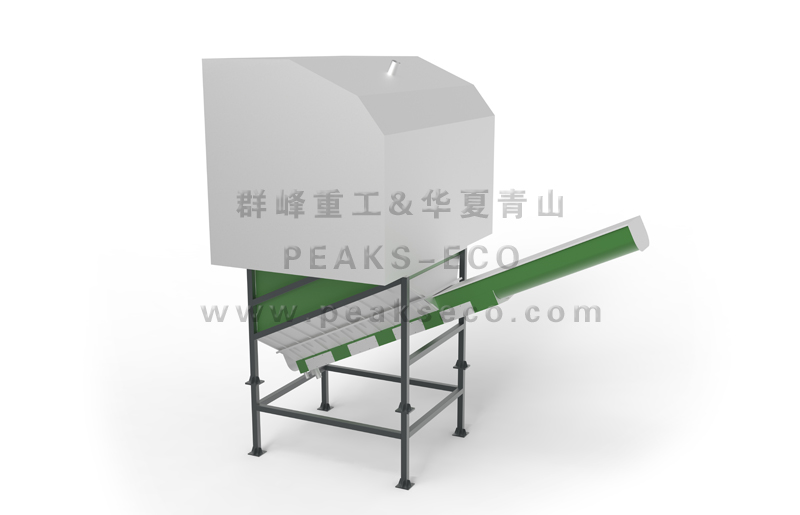

Manual sorting platform

In the process of construction waste treatment, the traditional sorting method is an artificial sorting platform. The artificial sorting platform of Qunfeng Heavy Industry is composed of a conveyor belt, a collection box, and a sorting room. It contains several workstations, and the staff is responsible for picking up impurities in aggregate on the conveyor belt and putting them into the collection box for unified treatment. Manual sorting mainly includes woodblock, aluminum alloy, plastic, wire and cable, and other impurities.

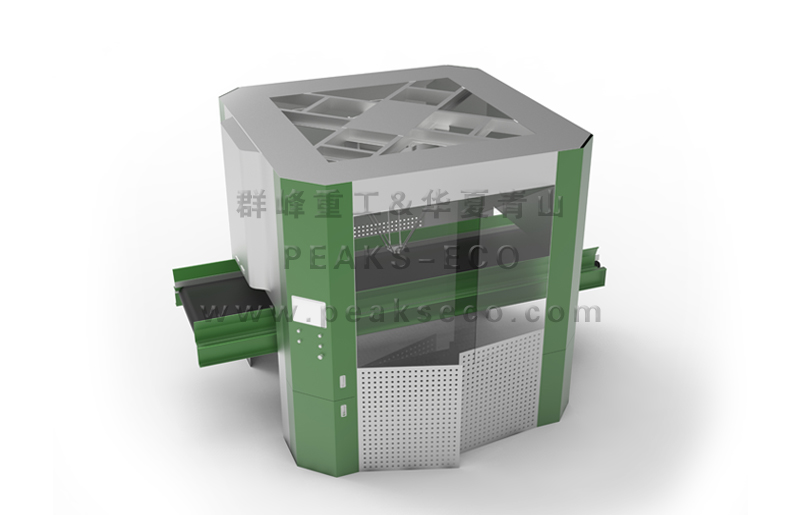

Peak-AI automatic sorting robot

The on-site working conditions of construction waste treatment are messy, dust pollution, unpleasant smell, and complex incoming materials. The Peak-AI automatic sorting robot developed and produced by Qunfeng Heavy Industry determines the position through instance segmentation, contour recognition, color recognition, and graphics algorithm. The material is recognized by 2D visual features, image recognition technology, and 3D geometric shape features. The grasping Angle is adjusted comprehensively through grasping position and pose search and interference judgment to realize a series of sorting work of construction waste.

The target product recognition rate of the Peak-AI automatic sorting robot is up to 95%, and the sorting times can reach 70 times per minute, which is twice the manual sorting speed (30-40 times per minute). The maximum grasping mass is 1.25 kg.

With the help of big data, artificial intelligence, and the Internet of Things, Qunfeng Heavy Industry keeps innovating and developing, deeply excavates the problems existing in the sorting process of construction waste and solves them, so as to ensure the quality and output of back-end recycled products from the source.

In the future, Qunfeng Heavy Industry will continue to expand its investment in artificial intelligence and further promote the recycling of construction waste.