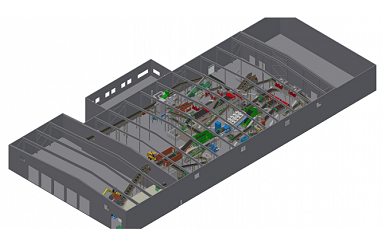

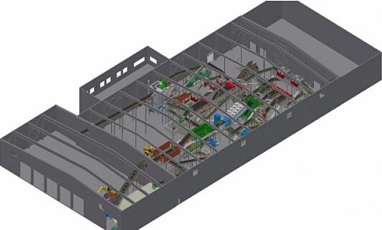

With the development of social economy and the enlargement of city scale and the improvement of peoples living standard, social waste is also increasing, which has caused the serious pollution. In order to handle this problem efficiently, it is necessary to build a perfect harmless treatment project of living waste. In fact, the waste is just another resource which has been put in the wrong place. If we disposed with an appropriate method, waste can also create a high value for us. In this respect, Peaks Eco has made a great adjustment in the waste composition and treatment process depending on domestic and international advanced technology, and produced a whole perfect garbage sorting machine.

If you are looking for a good waste sorting system manufacturer, Peaks Eco can be your better choice in China. Peaks Eco has been engaged in the waste recycling industry since its establishment. With advanced production technology and personalized service philosophy, we have become the industry leader. Peaks Eco garbage sorting system, possessing the top-rate sorting system, has made a great breakthrough on the structure. Furthermore, we can specially design the unique and automatic garbage sorting system according to the requirements of clients, subsequent treatment of resources, kinds of raw waste materials. By this method, our recycling sorting machine can ensure the highest profits for our costumers.