Food Waste Is “Difficult To Break The Bag", Everyone Is Discouraged, And Netizens Responded Brightly

Following the classification of garbage, the "broken bags" of kitchen waste has also become a topic of discussion after meals.

In the past, when we took out the trash, we put the trash directly into the trash bag. When the trash bag is full, it is sealed and dumped directly into the corresponding trash can.

Since the implementation of the new "Regulations on the Management of Domestic Waste in Beijing", some communities have strictly implemented the "broken bags" of kitchen waste as a new regulation for disposing of garbage. This regulation has discouraged everyone, and the responses of netizens have become a bright spot.

Recycling

(Netizens responded to the picture)

Food waste is composed of decomposable organic matter, and its two characteristics are the most obvious:

1. "Inborn" smell

2. a Large amount of penetrant

Sealing the garbage bag containing kitchen waste and dumping it into the trash can reduce the spread of odor and avoid the overflow of permeate. Now, you have to take out the garbage in the bag and put it into the trash can. The leftovers in the bag will inevitably flow out. Not only is it unsanitary, but the smell of kitchen waste will spread everywhere, which is counterproductive.

That being the case, why bother to "broken the bag" and then release it?

The main reason for the broken bags of kitchen waste is to facilitate the disposal of kitchen waste.

At present, aerobic composting and anaerobic biogas production are the main methods of recycling kitchen waste.

Aerobic composting: the use of microorganisms to re-decompose kitchen waste and turn it into waste. However, keeping food waste in a bag is not conducive to aerobic composting, and "hypoxia symptoms" will appear during composting, which will affect the composting effect.

Anaerobic biogas production and power generation: Although biogas production and power generation use anaerobic fermentation tanks, kitchen waste needs to be squeezed and shredded. During the treatment process, plastic bags are likely to be wrapped around the knife surface, squeezed blunt device, or rotating shaft. , Induce mechanical failure. If the plastic bag forms an airtight film in the anaerobic tank, it will also cause the biogas power generation system to collapse.

It can be seen that the food waste treatment method, whether it is aerobic composting or anaerobic biogas generation, needs to be broken bags first.

At present, various solutions have been proposed for the problem of “difficult to break the bag” of food waste, such as:

The peculiar smell of kitchen waste mostly comes from the undrained water taste in the garbage. In order to prevent the spread of the peculiar smell, it is necessary to drain the water before putting the kitchen waste;

Food waste can be cleaned every day. During the peak period of waste disposal, the frequency of collection and transportation can be increased, and the number and volume of collection containers can be increased;

Degradable plastic bags are used to store kitchen waste. The degradable plastic bags can be degraded during the composting process, but the degradation rate is slower than that of kitchen waste, and the price of degradable plastic bags is higher, which greatly increases the cost of waste disposal.

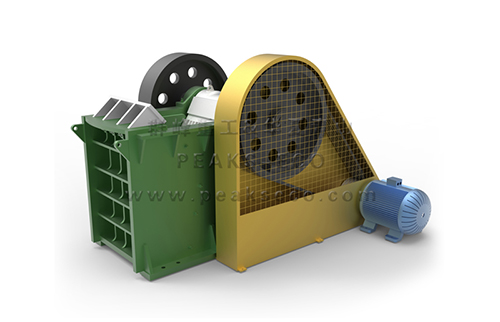

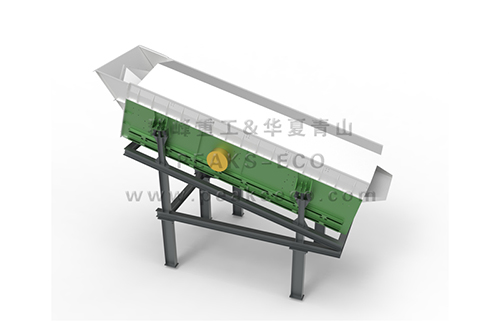

In addition, major kitchen waste treatment plants have also proposed solutions, introducing PEAKS organic matter separators, which are conducive to the back-end treatment of kitchen waste and reduces the pressure of back-end treatment.

When the PEAKS organic separator is running, the material is received by the upper hopper, and the material is conveyed to the organic lifting roller device through the active screw conveying. While the active screw is conveyed, the reverse screw at the upper hopper runs at the same time, which is opposite to the active screw to realize the bag braking function. After the material is transported to the organic lifting roller device, the lifting roller rotates at a high speed to lift the inorganic material to a certain height, and then it is output by the inorganic spiral; while the lifting roller is rotating at high speed, the material can be broken into The extremely small particle size is filtered out by the filter, effectively avoiding entanglement.

In addition, the system is equipped with a fully automatic control feeding system. The feeding system is coordinated and controlled by the management software. The screw feeding speed can be controlled according to the characteristics of the garbage materials and the feeding ratio provided to avoid the uneven feeding speed of the materials causing a blockage.

At present, PEAKS organic matter separator has been applied to various industries, except for kitchen waste and kitchen waste treatment plants, it is also widely used in paper mills, food processing plants, and other industries. With its exquisite design technology and unique treatment advantages Helped waste disposal and won a good reputation.

There is a certain degree of difficulty in breaking bags of kitchen waste. If you want to better solve the problem, on the one hand, you must encourage residents to take action, and on the other hand, you must use technology to sort the garbage into your home.