Qunfeng Heavy Industry & Huaxia Qingshan: Green Development, Create Resplendence!

The 19th China International Environmental Protection Exhibition (CIEPE2021) and the 2021 Environmental Protection Industry Innovation and Development Conference have begun the countdown, but everyone's enthusiasm has not faded. The exhibition brings together the leaders in the environmental protection industry. As a high-tech enterprise, Qunfeng Heavy Industry & Huaxia Qingshan made a wonderful appearance in the exhibition on the application and promotion of the latest technology and mainstream products of waste separation and successfully won people's attention for its advanced technology and green development attributes.

As a leader in the industry, Qunfeng heavy industry & Huaxia Qingshan is worthy of its name. It was selected from hundreds of enterprises to participate in the lecture meeting of "a hundred competitors compete for the top in environmental protection technology show". Zhang Wei, the general manager of our company, made a speech. Since its inception, the company has been adhering to the core concept of "green development, harmony and win-win", to build a well-known brand and achieve sustainable development of the company.

In this speech, General Manager Zhang Wei said that the company's solid waste treatment mainly includes two parts -- solid waste comprehensive treatment project and operation and waste transfer system project and operation. Solid waste comprehensive treatment projects mainly include domestic waste comprehensive treatment project, organic (kitchen and kitchen waste) comprehensive treatment project, construction waste comprehensive treatment project, recyclable waste sorting center project, dry slag pretreatment unit, garden waste comprehensive treatment unit, and anaerobic unit project, etc. Transfer station system project mainly includes large-scale vertical refuse transfer station project and operation and small and medium-sized intelligent refuse transfer station system project.

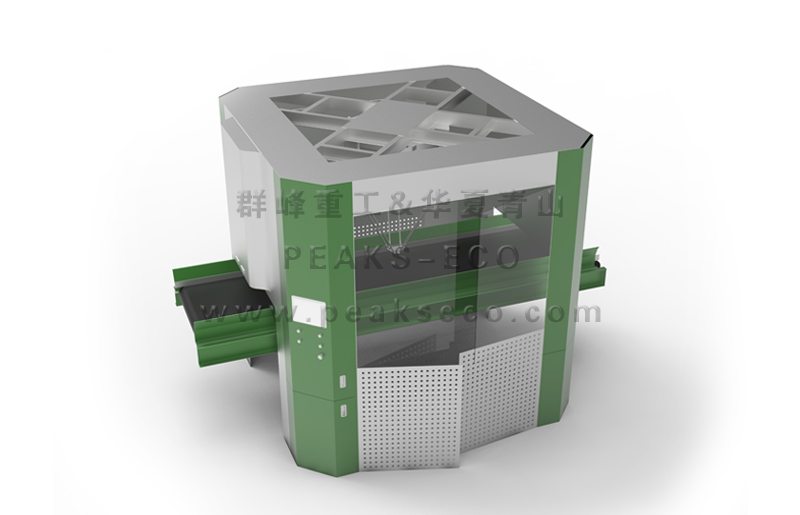

Since its establishment, the company has been taking the road of independent information research and development. The existing NIR optical separator, organic matter separator, Peak-AI sorting robot, vertical crusher, and so on are the mainstream equipment in the industry. Not only that, but the company has also reached a cooperation consensus with well-known enterprises at home and abroad such as Germany, the Netherlands, Europe, Finland, Taiwan, and so on, to jointly guarantee domestic waste pretreatment technology.

Scientific and technological innovation is the fundamental driving force for the development and progress of enterprises, and innovative technologies promote the continuous expansion and depth of the environmental protection industry. Qunfeng Heavy Industry & Huaxia Qingshan has strong independent innovation and strong production and processing capacity and has won recognition at home and abroad with excellent technical support and considerate service.

During the exhibition, the staff of our company warmly received each exhibitor, analyzed and explained every question provided by the exhibitor in detail, which left a deep impression on the participants and won high praise.

Near the end of the exhibition, Qunfeng Heavy Industry & Huaxia Qingshan said that in the future, we will continue to deepen our technology on the road of progress and provide careful and professional service to every customer. We are grateful to every customer and look forward to meeting with you next time!