Hydraulic baler machine is composed of a mainframe system, hydraulic system and auxiliary components.

1.Hydraulic packer-host frame system: solid thick steel plate aerated and welded and cast strong frame Advanced mechanical design makes the equipment durable.

2. Hydraulic packer-hydraulic system: Imported accessories are used for key components such as hydraulic pumps, solenoid valves and hydraulic cylinder oil seals, which make the packing pressure high, fast, durable and low noise.

3, hydraulic baler-electric control system (optional): original domestic electrical control, travel switch, button to ensure quality.

Principle and characteristics of hydraulic baler:

The hydraulic packer uses brand packer technology. It is now designed as a dual-circuit control of the whole machine, which is more stable and reliable than the previous single-circuit control. The dual-circuit control reduces the internal load of the machine's electrical board, and the circuit between the packer structure runs more smoothly. stable. As a manufacturer of hydraulic balers, the performance is more and more reliable, the quality is simpler and more convenient to inspect and debug, and the photoelectric clutch control is adopted in the clutch.

Working principle of hydraulic baler machine: packing is completed by tensioning, heat capacity, tape cutting, and bonding. The baler factory produces a wide range of uses. Regardless of the size of the packaging, you can pack without adjusting the machine. The hydraulic baler is a mechanical structure and some of the imported baler parts are used. In the era of the rapid development of packaging machines, each enterprise is considering its own production costs and its user experience. In mechanical production, how to present automation and replace manual operations with lower efficiency, reducing human resources costs, has become a The big core.

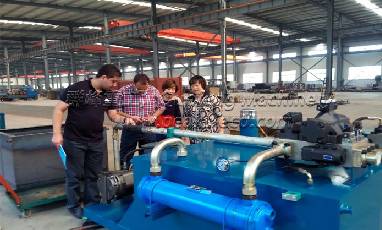

Hydraulic Baler Machine

In the assembly line production of the hydraulic packer, the main points are good starting and speed regulating performance and strong overload capacity. For the hydraulic packer equipment, in addition to the reasonable selection of the opening pressure according to the needs, special attention should also be paid to the work. When the flow through the check valve is much smaller than the rated flow, the check valve sometimes vibrates, and the smaller the flow is, the more The higher the pressure, the more the gas content in the oil, the more likely it is to vibrate, which is also necessary to pay attention to when using it.

The hydraulic packer is mainly used for recycling packaging materials such as compressed cardboard, waste film, waste paper, foam plastic, beverage cans and industrial scraps, and waste products. In addition, this vertical baler reduces waste storage space, saves up to 80% of storage space, reduces transportation costs, and is conducive to environmental protection and waste recycling.

Hydraulic metal baler is also expanding in more areas:

The hydraulic packer is also suitable for steel plants, recycling processing industries and non-ferrous and ferrous metal smelting industries. The hydraulic packer can extrude various metal scraps into qualified shapes such as cubes, octagons, cylinders, etc., which can reduce transportation and smelting costs, and increase furnace speed.