With the increase of the urban population, waste sorting machines have become popular in many countries. Recently, municipal waste has shown an increasing trend. Facing the large amount of waste generated by human beings, how do we quickly realize the classification of waste? The answer is a fully automatic garbage sorter. This kind of recycling equipment makes garbage sorting easier. At the same time, the machine will save a lot of labor costs.

The garbage sorter is designed based on the principle of reducing the volume of garbage and turning waste into treasure. By using various efficient garbage sorting systems, we can obtain organic, plastic, metal, brick, stone, etc. from the garbage. The classification rate of the above garbage can reach more than 85%, and the classification rate of film plastic can reach more than 90%.

Do you know the characteristics of the Sorting machine MSW china?

1. Rotating screen machine. The rotary screen machine is mainly used to select large materials larger than 50mm and small materials smaller than 50mm. This process effectively divides waste into two types. In addition, according to the different needs of customers, we can also add blades inside the rotary screen to achieve the breaking effect.

2. Smooth automatic document feeder. This paper feeder can automatically transfer the garbage to the next garbage sorting process, thus saving manpower. In addition, the machine can evenly distribute garbage on the belt, so that the next operation is more smooth.

3. PLC system. The PLC control system can monitor the entire working process of the solid waste management system. Once anything unpredictable happens, we can make adjustments in time. Therefore, the machine greatly guarantees the safety of the garbage sorting equipment.

4. Comprehensive winnowing machine. The comprehensive winnowing machine adopts several garbage classification principles, such as specific gravity method, volume method, cyclone separation method, etc. Waste is mainly divided into three types: plastic film and mixed materials (hard plastic, rubber products, miscellaneous paper). , Textiles, etc.) and heavy objects (bricks, stones, rubber overshoes, glass, etc.). After being processed by this garbage classifier, the sorting rate is greatly improved.

What materials can be sorted from garbage? What can these classified materials do?

As we all know, garbage is composed of plastic, tree branches, chicken manure and other different wastes. In different countries, there is a big gap between the composition of waste. We want to know your detailed information and will design a suitable solid waste recycling plant for you.

1. Waste plastic. There are three ways to recycle waste plastics. The first is to use a waste plastic pyrolysis machine, which can turn plastic into oil. Secondly, certain materials in plastics can be used as rubber reinforcing agents. Third, we can sell waste plastics to other industries to make new plastic products.

2. Stone, sand, and waste building materials. Do you think these wastes are useless? However, we can use these wastes to make bricks through the brick machine production line. Nowadays, the technology of making bricks from the mud, stones, sand or carbon black in pyrolysis garbage is fully mature.

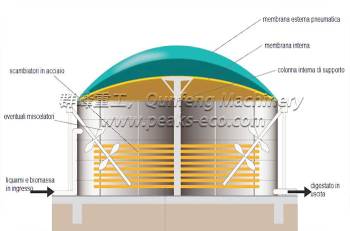

3. Organic matter. After selecting some unusable materials, we can send the organic matter to the fermentation system, and then the system will produce biogas as energy.

4. Scrap metal. After packaging with a packaging machine, scrap metal can be sold directly to other industries to manufacture new metal products.