The Loss Rate Of Food Waste Organic Matter Is High, How To Extract Organic Matter With High Efficiency And Proportion?

Characteristics of kitchen waste:

· High moisture content

· High protein content

· High oil content

· Perishable

Combined with the characteristics of kitchen waste, its treatment method should also adopt a modern mechanized sorting method, sorting, and separation of kitchen waste, so as to effectively separate out impurities, get high purity organic matter, more conducive to recycling.

It is understood that the national planning and construction and has been built and put into operation of kitchen and kitchen waste and other organic waste treatment projects selection process, completed part of the project because of various problems led to "stranded, paralyzed", the main reasons for the following aspects:

· Defects in system design and errors in process calculation;

· Low extraction rate of organic matter, unable to meet the back-end process treatment;

· Defects in equipment manufacturing and lack of experience in equipment selection;

· Outcomes (biogas, biodiesel, and waste) involve multiple professions, and lack of operational experience makes it difficult to control the whole industry.

As a typical perishable waste, the disposal of kitchen waste can avoid environmental pollution, and it is also a kind of recyclable material.

At present, the recycling technology of kitchen waste, aerobic and anaerobic treatment technology has been mature and reliable, aerobic and anaerobic biotechnology is completely dependent on the organic matter in kitchen waste, and if there are a lot of impurities in the waste, it will affect the success of the application of biotechnology. The organic matter in the kitchen waste is everywhere. Its shadow can be seen in the solid phase, the liquid phase, and even the gas phase. Then how to extract the organic matter in the waste with high efficiency and high proportion is the most important, which is directly related to the success or failure of the resource treatment of kitchen waste.

Exquisite technology, rich project experience, professional industry talents, and high-quality after-sales service, which is closely related to the recycling treatment of kitchen waste. The kitchen waste pretreatment system of Qunfeng Heavy Industry & Huaxia Qingshan solves the problem of too many and mixed impurities in the kitchen waste, and not only that but also solves the problems of high loss rate of organic matter and oil and serious equipment wear in the traditional pretreatment system, so as to realize the resource utilization of kitchen waste.

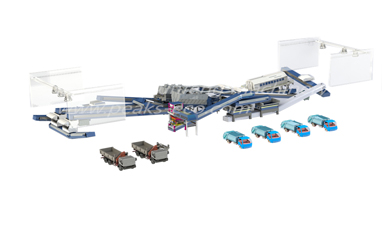

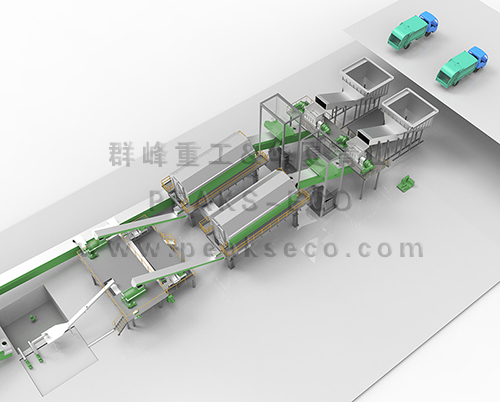

The system mainly includes a feeding system, crushing system, screening system, pulping and pressing system, heating cache system, three-phase separation system, etc.

Feeding system

· The silo can meet the rapid and continuous discharge of incoming materials;

· The water collection function of the silo is comprehensive, and it can prevent the oil from condensing;

· Seal and deodorize the silo, and realize continuous operation in the discharge process;

· Preventing blockage and winding of silo

· It is suitable for the treatment of household waste, kitchen waste, and construction waste with large dust

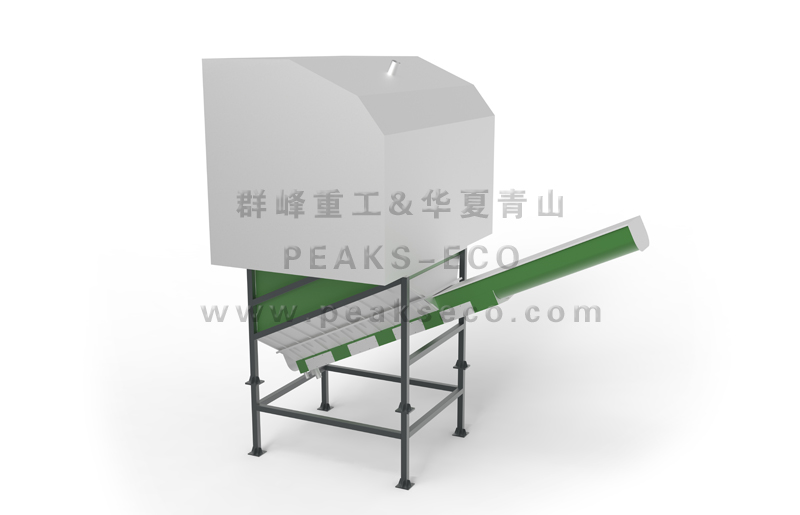

A broken system

Although the composition of kitchen materials is not complicated, there are large particles in kitchen waste. The crushing system can reduce the pressure of back-end conveying equipment and fine pulping.

Screening system

Food waste will inevitably have spoons, chopsticks, and other magnetic materials, the use of magnetic separators can be screened out of this kind of material. The metal separation system uses permanent magnets to separate the iron from the waste without the need for a motor drive. Conveyor belts revolve around huge permanent magnets to separate wire, nails, and gas canisters. The body of the magnetic separator is made of steel structure, non-magnetic, so as to avoid the iron material on the body of the magnetic separator.

Kitchen waste is a kind of valuable and available resource, the real realization of waste resource utilization is the greatest value. The kitchen waste pretreatment system of Qunfeng Heavy Industry & Huaxia Qingshan can carry out sorting and separation of garbage, better meet the requirements of aerobic or anaerobic utilization at the back end and truly realize waste reduction, harmless and resource utilization.